Questions to Ask Before You Buy a Mobile Column MP Series Lift

Click the questions to view the answers and click images below questions to enlarge.

Click the questions to view the answers and click images below questions to enlarge.

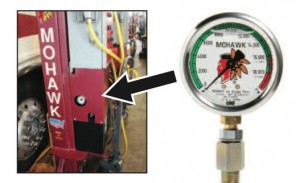

With Mohawk’s direct drive hydraulic lifting system there is no need for excessive monthly maintenance

A 12” long fork won’t fully engage a floatation tire and certainly won’t grab both rear tires. Mohawk Lifts lifting forks are able to raise both dual rear tires.

The first image shows a Mohawk Lift with lifting forks lifting both dual rear tires. The 2nd image is a Rotary lift. The third image is a Steril Koni Lift.

If not then the lift is no longer certified. All but one of Mohawk’s mobile lift accessories are ALI/ETL certified to meet the one and only nationally recognized safety standard for vehicle lifts. Just look for the mark. For additional information visit www.autolift.org.

If not then the lift is no longer certified. All but one of Mohawk’s mobile lift accessories are ALI/ETL certified to meet the one and only nationally recognized safety standard for vehicle lifts. Just look for the mark. For additional information visit www.autolift.org.

If not how do you know the lift has been fully lowered on the locks?

If not how do you know the lift has been fully lowered on the locks?

Mohawk Lifts offers an ALI/ETL certified weight gauge that aides vehicle diagnosis by measuring weight within 3% of vehicle weight.

If not then you’ll always need to raise passenger vehicles with all 4 columns. Mohawk Lifts offers auto frame adaptors that quickly slide over lifting forks & allows two columns to raise cars & light trucks by the frame or bumper to leave the wheels free

Adjustable forks can’t slip off like a wheel reducer sleeve or be forgotten as fixed forks require the reducer sleeve be added and removed.

If not, plows will need to be removed (2-3 Hours) before raising a plow truck. Mohawk Lifts offers a wing plow adaptor or RV slide out which allow winged snow plow trucks to be raised without removing the plow and allow RV slides to be extended and lifted.

Accommodating larger rims is important for military vehicles, or vehicles with 24” rims. Mohawk’s standard columns accommodate a 24” rim.

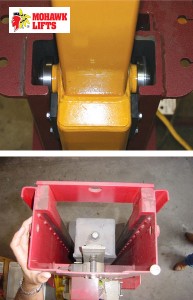

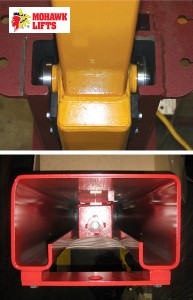

Mohawk lifts are made with fork lift masts. Fork Lift Masts last forever, vs. bent sheet metal which is weakened sheet metal.

The first photo shows a Mohawk Lift on the top and an ALM brand lift at the bottom. The second photo shows a Mohawk at the top and a Rotary lift on bottom. You can see that Mohawk Lifts are made with fork lift masts.

Headquartered in Amsterdam, N.Y Mohawk lifts are proudly designed, welded, and manufactured in the U.S.A. Buying American made products ensures parts and service availability, supports the U.S economy, and support the American workforce.

Replacements for Mohawk’s off the shelf PLC’s can always be found while dedicated circuit boards can cost $30,000 (If ever needed).

Mohawk’s dual bearing enclosed rubber coated steel wheels make the column the easiest to move and position as its rubber coating allows for easier rolling over shop debris & expansion seams.

The 1st photos show Mohawk’s rubber coated dual wheels that allow for easy rolling. The bottom images show competitor’s plastic or steel wheels.

If not, is the floor perfectly flat as required by some column brands? Mohawk’s slope indicator attaches to the column to display the floor slope measured in degrees. Other brands mandate level floors with no more than a .06° slope.

If you’ve not seen the MEEP (Management Evaluation Equipment Program) report, ask for it. View Mohawk’s MP-18AC MEEP evaluation.

If you’ve not seen the MEEP (Management Evaluation Equipment Program) report, ask for it. View Mohawk’s MP-18AC MEEP evaluation.

If not able to be divided, you’ll never make a set of 4 into 2 sets of 2. Mohawk mobile columns can operate in pairs and sold in sets of 2, 4, 6, or 8 columns. If you purchase 4 Mohawk mobile columns today you could add two columns later as your fleet grows and needs change.

Mohawk’s paired Mobile Columns have power sources on all pairs enabling the user to divide the columns and still have power access. Some competitors only offer 1 main power post which doesn’t allow the user to divide the columns or add columns as their fleet grows.

Mohawk’s 22” forks still have a capacity of 16,000 lbs per column while some lift brands decrease capacity by 33% (yet 24,000lb isn’t enough to raise some vehicles with heavy rear ends).

If not, then the lift itself is no longer certified. Mohawk’s jack stands are ALI/ETL certified. The use of non certified jack stands will void lift certification.

For example 24,000 or 30,000 lb rear columns combined with 18,000 front columns. Mohawk MP-18’s can be combined with Mohawk’s MP-24 or MP-30 mobile column lifts.

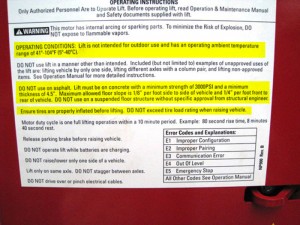

Every lift comes with different warning labels. Ask to see them before you make a lift purchase.

Competitor warning label warns users not to:

Mohawk understands that lifts operate in many conditions and Mohawk has worked hard to brings users a quality products that fits all of your lifting needs (hot, cold, or not perfectly level shop floors).

Mohawk’s mobile column distributes the load over a greater surface area with retractable front wheels spreading the load vs lifts with just “point loads” resting on their wheels.

The first image shows a Mohawk mobile column that broadly distributes the load evenly. The second image shows a Steril Koni lift. The third image shows a Sefac lift. Please note that these columns don’t sit on he floor as do Mohawks.

Mohawk’s DC mobiles allow 31 cycles.